Blog #8 - Finalizing UH Race-Car For the Competition

- FSAE Suspension Team

- Apr 17, 2020

- 2 min read

Updated: Apr 17, 2020

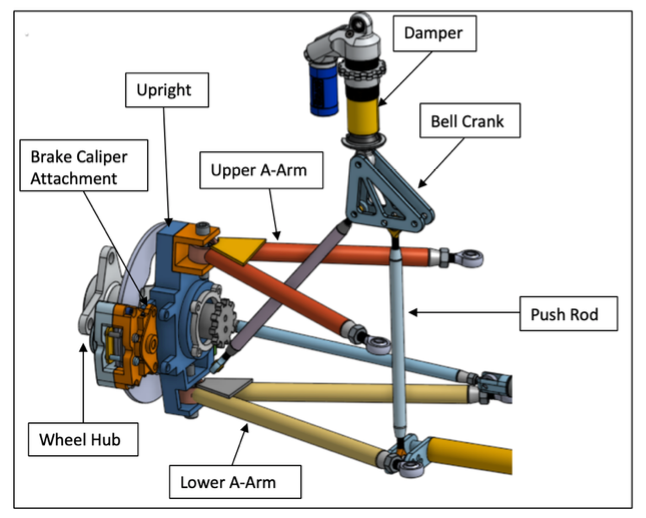

The team has achieved the final design requirements for the FSAE competitions and the client’s requirements. The front and rear suspension packages are shown in Figure 1&2. The team designed the Uprights, Bellcranks, A-arms, anti-roll bars, and all the other tubing, tabs, and attachments. Team 9 started analyzing the tires and the kinematic motions before designing the suspension system. After that, the CAD modeling took several iterations to be altered and exactly fit the needs of the FSAE team. For example, the team made more than 3 versions for the front and rear uprights. The uprights were designed to withstand all the forces while allowing flexibility for Camber adjustments. The motion of the suspension system from the optimumK software is shown below.

The team was progressing in the manufacturing process, and most of the parts were fabricated either at a sponsor’s shop or the FSAE shop. The next planned process was the assembly and validation process. It was previously planned that the team will measure the deflection of the uprights using weights, proximity probes, and strain gauges to test the uprights. However, the team couldn’t meet in person, assemble the parts and validate them.

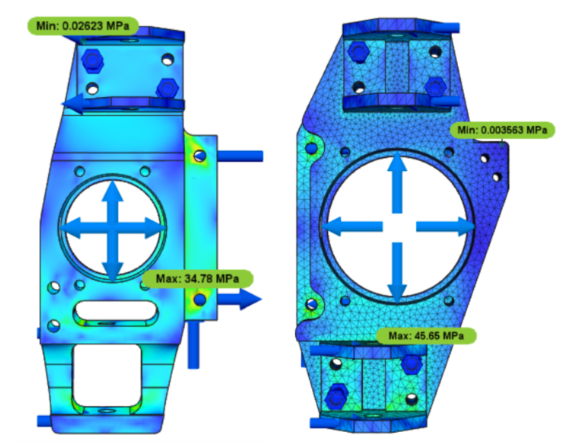

Therefore, a new validation plan was implemented to ensure that the most important suspension components are going to withstand the forces exerted by the motion and weight of the car. The team worked on expanding the FEA analysis previously done. The new FEA analysis is more detailed for each section of the uprights and is focusing on three main cases. The cases are maximum braking, maximum acceleration, and maximum cornering. After testing both uprights under these cases, the parts showed a safety factor of at least 4 (Figure 3). Also, the stress concentration analysis showed the expected results ( Figure 4).

Therefore, a new validation plan was implemented to ensure that the most important suspension components are going to withstand the forces exerted by the motion and weight of the car. The team worked on expanding the FEA analysis previously done. The new FEA analysis is more detailed for each section of the uprights and is focusing on three main cases. The cases are maximum braking, maximum acceleration, and maximum cornering. After testing both uprights under these cases, the parts showed a safety factor of at least 4 (Figure 3). Also, the stress concentration analysis showed the expected results ( Figure 4).

The team was expecting the validation results because the design of the upright took several iterations to become as strong as possible while optimizing the weight of its body and the time of machining it. Team 9 aimed to physically test the uprights, and validate if the deflection was going to affect certain areas of the uprights or whether cracks were going to initiate at unexpected parts. However, due to the circumstances caused by the COVID 19 virus, the team does not have any other options to validate the suspension system and assemble it. Also, The car will be used for the FSAE 2021 competition due to the FSAE 2020 competition being canceled.

Comments